Quality Control

Company Quality Control of GISON Air Tools

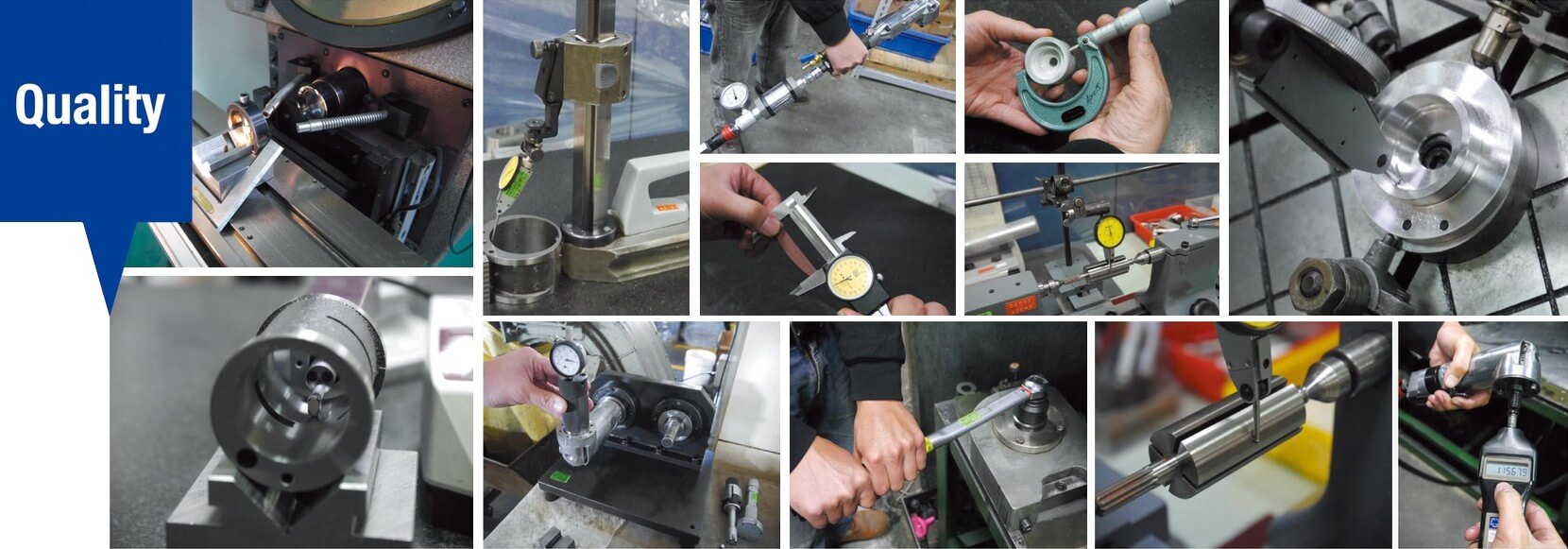

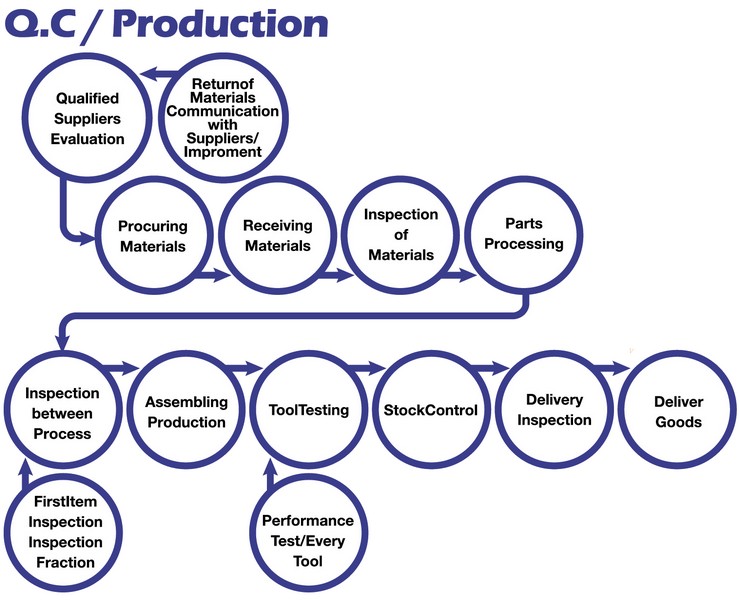

To strictly control the quality of parts in every processing stage, Gison and the parts suppliers accomplish the Quality Control according to the same inspection standard by using precision instruments. Every staff in Q&C department. is well trained and qualified.

The instruments are analyzed and adjusted regularly by professional organization to ensure correct and efficient parts examination. To ensure the quality of parts, First inspection, Inspection on the spot and Inspection by sampling are required during parts production. Final product testing is the most important stage before offering perfect air tools to customers.

We get material of the most significant from Japan to ensure our quality stability and accuracy. CE is declared since 1996. Our quality system has been certified under ISO-9001 standards since 1996, and that allows us to maintain the quality of our products.

With extensive product knowledge, stable workforce along with reliable & dedicated performance, GISON seeks to provide the best possible & most reliable products to you directs all the efforts to reach our goal.

● Superior quality you can always trust

● Best price for best competitiveness

● Professional skill on which you can rely

● Pioneer products to keep ahead of others

● Quick service-after-sale to keep you always satisfied

- MoviesFiles Download